Battery Recycling Innovation Park

Akkujen kierrättämiseen ja kiertotalouteen keskittyvä innovaatiopuisto, jossa yrityksillä ja T&K-toimijoilla on mahdollisuus käynnistää tuotekehityshankkeita, liiketoimintaa ja kansainvälistä yhteistyötä aktiivisessa ja verkottuneessa toimintaympäristössä.

Toimiala: Tuotantoteknologia

Projektin kesto: 1.1.2020 -30.6.2023

Toiminta-alue: Pohjois-Pohjanmaa

Rahoittajat: Euroopan aluekehitysrahasto

Pohjois-Pohjanmaan liitto

Battery Recycling Innovation Park on Euroopan aluekehitysrahaston (EAKR) rahoittama hanke, joka käynnistyi toukokuussa 2020. Hankkeen tavoitteena on luoda Ylivieskaan litium-ioni akkujen kierrätysinnovaatioihin ja kiertotalouteen keskittyvä akkuteollisuuden innovaatiopuisto. Keskeisiä tutkimus- ja kehittämisalueita ovat akkujen testaus ja kunnon arviointi, käytettyjen akkujen käsittelyprosessin automatisointi, robotiikka, Industry4.0 ratkaisujen soveltaminen, erilaisten simulaatioiden ja virtuaalisen testausympäristön kehittäminen (koetehdas), turvallisuus ja logistiikkaratkaisut, ICT sovellukset jne. Hanketta hallinnoivat Ylivieskan kaupunki, Centria ammattikorkeakoulu ja Sievin Teollisuuspuisto Oy.

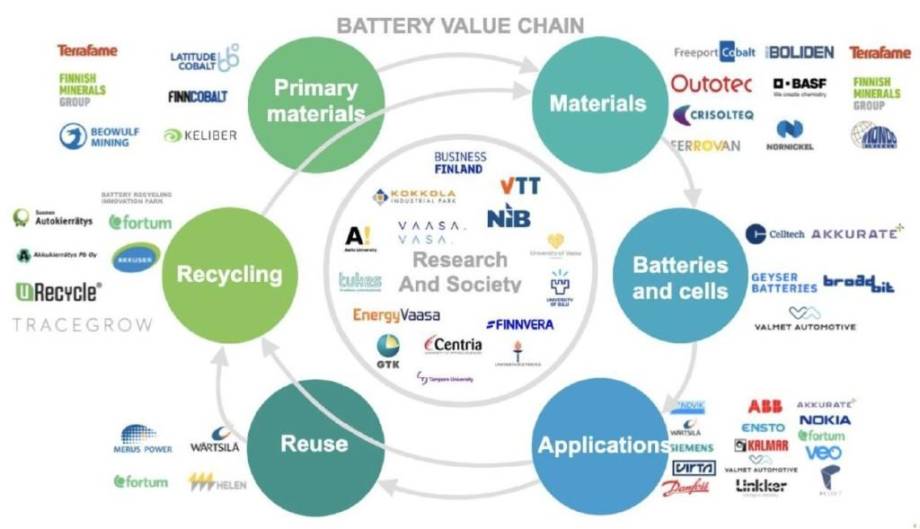

Akkujen kierrättämiseen ja kiertotalouteen keskittyvän hankkeen tavoitteena on luoda Ylivieskaan akkuteollisuuden innovaatiopuisto sekä siihen liittyvä yritys- ja kumppaniverkosto. Olemme kartoittaneet start-up -yrityksiä, pk-yrityksiä, suuryrityksiä ja T&K-toimijoita, ja tällä hetkellä noin 50 yritystä on nyt vahvistanut kiinnostuksensa olla mukana projektin kumppaniverkostossa. Yrityksistä noin puolet on ulkomailta ja puolet Suomesta.

TP 01 Battery Recycling Innovation Park kehitysaskeleet (Ytek)

6-vaiheisen mallin kierto: Toisen vuoden aikana toistuvat tarkentavat vaiheet 1-6

Vaihe 1: Kartoitetaan osapuolten väliset synergiavaikutukset

Vaihe 2: Luodaan yhteinen visio akkupuistosta

Vaihe 3: Rakennetaan yritys- ja kumppaniverkosto

Vaihe 4: Luodaan liiketoimintamalli

Vaihe 5: Luodaan strategia Invest-In -toiminnoille

Vaihe 6: Pilotoidaan uusia liiketoimintamalleja ja mahdollistetaan toiminta

TP 02 Jäännösmateriaalivirtojen ja käyttötapausten kartoitus (Centria)

Tehtävä 1: Materiaalien kartoitus

- Akkujen materiaalivirtojen kartoitus ja kuvaaminen mukaan lukien

A) potentiaaliset kierrätysmateriaalit

B) mahdollinen jäännöskapasiteetti - Menetelmät: Kirjallisuus, tutkimustulokset, laboratorioanalyysit Centrian tiloissa

Tehtävä 2: Teollisuuden digitalisaation (Industry 4.0) sovellusmahdollisuudet akkujen kierrätysprosessissa

- Hyödynnetään uusimpia laboratorioinvestointeja demonstroinnissa, toimintaympäristöjen kehittämistarpeiden ja tulevien teknologioiden kartoittamisessa akkujen kierrättämisen näkökulmasta

- Tutkitaan nykyisten ja tulevaisuuden tuotantoteknologiasovellusten käyttöä akkujen kierrätysprosessissa

- Keskeisimpinä tutkimusalana robotti- ja cobottisovellukset, konenäkö ja muut tunnistamisteknologiat (RFID, 2D-viivakoodit)

- Tutkitaan uusimpien ja tulevaisuuden tunnistamisteknologioiden kuten 2D ja 3D-tunnistuksen, läpivalaisuteknologioiden ja erilaisten liikkuvien robottien hyödyntämistä integroitujen ja/tai murskattujen akkujen automaattisessa tunnistamisessa

- Automatisoitujen purkulinjastojen kehittäminen

- Tutkitaan tekoälyä ja koneoppimista tunnistamisdatan tulkitsemisessa sekä näiden teknologioiden tulevia sovellusmahdollisuuksia akkujen kierrätysteollisuudessa

- Uusien teknologioiden, esim. akkujen kierrätyslaitosten ja kiertotalousympäristöjen digitaalisten kaksosten tutkimus, tavoitteena

- tuottaa tietoa esim. akkutyypeistä, vikatilanteista ja prosessin eri vaiheista akustonvalvontajärjestelmän (BMS) vaatimuksiin

- kehittää tuotantolaitosten prosesseja ja simulaatiomalleja ja luoda suotuisa ympäristö integroituun ja kattavaan prosessioptimointiin

- parantaa laitosten ja koko kierrätysverkoston etäohjaus ja -konfigurointivalmiuksia

Turvallisuus

- Tutkitaan prosessointi- ja työskentelyalueiden turvallisuuden mahdollistavien etäohjattavien lennokkien käyttöä

- Pöly, akkumateriaalien ylikuumeneminen ja kaasuuntuminen kuljetuksen, varastoinnin ja käsittelyn aikana muodostaa kierrätysprosessissa merkittävän palo- ja räjähdysriskin

- Ilman puhtaus on tärkeä myös henkilöstön työskentely-ympäristön näkökulmasta

- Kartoitetaan IoT-ratkaisuja, joilla prosessointi- ja varastoympäristöjä voidaan hallita kaasu, pöly ja lämpötilasensoreiden sekä lämpökameroiden ja optisten antureiden avulla

- Tutkitaan liikkuvien robottien ja dronejen roolia käsittely-ympäristössä tapahtuvien korkeatasoisten mittausten turvallisuuden lisäämiseksi

- Akkujen logistiikkaketjuja koskevassa tutkimuksessa hyödynnetään Industry 4.0 -sovelluksia, joilla voidaan hallita esim. akkujen kierrätysastioiden ylitäyttymistä, josta voi aiheutua vaaraa ympäristölle

Tehtävä 3: Kierrätysmateriaalivirrat

Tehtävä 3 toteutetaan niiden tietojen perusteella, joita TP2:ssa saadaan akkujen koostumuksesta ja jäännöskapasiteetista

- Tavoitteena on tutkia nykyisten akkutyyppien sekä uusimmalla valmistusteknologialla valmistettujen akkujen jäännösmateriaalikapasiteettia. Tämä käsittää:

a) kierrätysominaisuudet

b) uudelleenkäyttöominaisuudet

c) toteuttamiskelpoisen arvoketjumallin, jossa materiaalien arvo voidaan todentaa mahdollisimman pitkään - Otetaan huomioon täysin uudet ja mahdolliset vaihtoehtoiset käyttökohteet sekä akkumateriaalien uudelleenkäyttö

- Verrataan jo yleisessä käytössä olevia akkujen kierrätys- ja uudelleenkäyttömalleja ja niiden soveltuvuutta kierrätysinnovaatiopuiston tarpeisiin

TP 03 Biohiili ja grafiitti akkuteollisuudessa (Sievi Industry Park)

- Biopohjaisesta hiilimateriaalista saatavan grafiitin soveltuvuus akkujen anoidimateriaalien korvaajaksi

- Biopohjaisten hiilimateriaalinsovellusten kierrätysominaisuuksien tutkiminen

- Biohiilipohjaisen grafiitin käyttö uusien akkuteknologioiden kehittämisessä, esim. suola-akkujen raaka-aineena vaihtoehtona litiumioniakuille.

- Yksi biohiilipohjaisten materiaalien kuten grafiitin käytön eduista on se, että niiden varaus voidaan purkaa kokonaan, jolloin niiden kuljetus on turvallisempaa. Tällä hetkellä suola-akkujen lataussyklit eivät ole tarpeeksi pitkiä, jotta ne voisivat kilpailla litiumioniakkujen kanssa, mutta teknologian kehittyessä niiden käyttökohteet voivat lisääntyä huomattavasti

TP 04 Tilojen ja välineiden suunnittelu (Ytek)

- TP1:ssä muodostetaan kiertotalous- ja sidosryhmäverkosto ja hankinnat suunnitellaan sen mukaisesti

- Välineiden ominaisuuksissa otetaan huomioon osallistuvien yritysten tarpeet

- Välineet tutkimukseen ja pilotointiprojekteihin

- Nykyisten laboratorio- ja toimistotilojen uudelleenjärjestely

- Mahdolliset uudet tilat

TP 05 Projektin koordinointi (Ytek)

Projektin hallinnollinen kokonaiskoordinointi.

Hankkeen tarjoamat resurssit ja palvelut yhdessä yritys- ja kumppaniverkoston kanssa mahdollistavat uusien liiketoimintamallien kehittämisen, yritysten ja T&K-toimijoiden yhteiset tutkimus- ja tuotekehityshankkeet sekä kotimaiset ja kansainväliset kontaktit ja yhteistyön. Pystymme tarjoamaan kiinnostuneille yrityksille laboratorio-, testaus ja toimitiloja sekä robotteja ja muita laitteita tuote- ja palvelukehityksen tarpeisiin helpottaen yritysten mahdollisuuksia kehittää uusia ratkaisuja akkuteollisuuteen, akkujen kierrätykseen ja esimerkiksi niihin liittyviin energiaratkaisuihin.

Tällä hetkellä selvitämme myös mahdollisuuksia toteuttaa li-ion akkujen pilottikierrätyslaitos ja virtuaalinen kehittämisympäristö osana innovaatiopuistoa. Syyskuussa 2021 käynnistynyt rinnakkaishanke, BR Pilot Plant, ja Centria ammattikorkeakoulun sähköautojen akkujen robotisoitua purkamista kehittävä SAAROB-hanke tukevat uuden yritystoiminnan ja akkuklusterin syntyä alueelle.

Taustaa

Akkujen käyttöä vauhdittavat erityisesti sähköiseen liikenteen ja uusiutuvan energian käytön kasvu, ja akkumarkkinoiden arvon onkin Euroopassa ennustettu olevan 250 miljardia euroa vuoteen 2025. Suomessa on laajaa akkuarvoketjuun liittyvää osaamista: vahvaa kaivosteollisuutta ja raaka-aineiden prosessiteollisuutta sekä akkujen valmistamiseen, käyttöön ja kierrätykseen liittyvä teknologiaosaamista. Ilmastonmuutos ja hiilijalanjäljen pienentäminen ovat luoneet valtavan kysynnän kestävän kehityksen mukaisille akkujen kierrätysteknologioille ja Suomen tavoitteena on päästä johtavaksi teknologia- ja palveluasiantuntijaksi globaaleilla markkinoilla.

- Robotiikka ja konenäkösovellukset

- XRF (röntgenfluoresenssi) ja optiset lajitteluteknologiat

- Jännitteen purkaminen ja akkujen testausteknologiat

- Akustonvalvontajärjestelmä (BMS)

- Akkukennojen second life -käytön vaihtoehdot

- Akkumateriaalien uudet käyttökohteet ja kierrätysasteen kasvattaminen

- Korkeampia raaka-ainepitoisuuksia sisältävien tuotteiden tunnistaminen ja talteenotto kierrätysprosessissa

- Akkujen turvallinen hävittäminen ja purkuprosessiteknologiat

- Lisätä tietoa nykyisistä ja tulevaisuuden akkurakenteista ja -tyypeistä

- Löytää akkuteollisuuden ja muun teollisuuden tarpeiden näkökulmasta kiinnostavimmat kierrätettävät akkumateriaalit ja materiaaliyhdistelmät

- Materiaalien tehokkaampi kierrätys

- Materiaalien erottelu- ja talteenottoprosessien kehittäminen ja parhaan materiaalimuodon löytäminen

- Kierrätetyistä harvinaisista metalleista saatavat välituotteet

Arvon muodostuminen akun elinkaaren aikana

Centria-ammattikorkeakoulu

Centrian tutkimus- ja kehittämisyksikkö tekee yhteistyötä yritysten ja organisaatioiden kanssa niiden kilpailukyvyn vahvistamiseksi. Centrian tavoitteena on tarjota monialaista osaamista yritysten avuksi tuotekehitykseen, liiketoimintahankkeisiin, kansainväliseen toimintaan ja yrittäjyyteen.

Centrian T&K-toiminta on yksi ammattikorkeakoulun vahvuuksista ja sen taso ja laajuus on Suomen ammattikorkeakoulujen kärkeä. Centrian vahvuutena ovat sen poikkeuksellisen tiiviit yhteydet alueen elinkeinoelämään. Paikallisen elinkeino- ja työelämän osuus tutkimus- ja kehitystoiminnan rahoituksesta on ollut noin neljännes.

Centrian tutkimus- ja kehitysyksikkö työllistää n. 110 henkilöä, ja tutkimus- ja kehityshankkeita on käynnissä vuosittain noin 90. Suurimmat tutkimus‐ ja kehityshankkeiden julkiset rahoittajat olivat Business Finland, EU (EAKR, ESR, Interreg), maakuntien liitot ja ELY‐keskukset.

Vuonna 2019 Centrian T&K-toiminnan kokonaisvolyymi oli 8 milj. €, josta ulkopuolisen rahoituksen osuus oli 6,6 milj. €, mukaan lukien viisi Business Finlandin hanketta, joiden rahoitusosuus oli 2,6 milj. €.

Ylivieskan kaupunki

Ylivieska on Pohjois-Pohjanmaalla sijaitseva alueellinen keskuskaupunki. Ylivieskan kaupungin elinkeinopalvelut tukee ja kehittää yritysten toimintaedellytyksiä sekä kannattavan liiketoiminnan ja uusien työpaikkojen syntymistä Ylivieskaan.

Ylivieska on yli 100 000 asukkaan markkina-alueen keskus, joka tarjoaa hyvät palvelut ja puitteet mukavaan elämään, henkilökohtaiseen kehitykseen ja monipuoliseen liiketoimintaan. Sen sijainti pääradan varrella ja valtatien 27 ja kantatien 86 risteyksessä takaa nopeat liikenneyhteydet kaikkialle. Oulunsalon ja Kruunupyyn lentokentät ovat lähellä, samoin Kokkolan ja Kalajoen satamat.

Ylivieska on tunnettu kaupan keskus ja vetovoimainen autokaupan keskittymä. Teollisuuden aloista etenkin metalliteollisuus, elektroniikka- ja mekaniikkateollisuus sekä mekaaninen puutuoteteollisuus ovat vahvoja ja alue on maanlaajuisesti tunnettu tuotantoteollisuuden keskittymä.

Sievin Teollisuuspuisto Oy

Sievin Teollisuuspuisto Oy on kokonaisuudessaan Sievin kunnan omistama yhtiö, joka tuottaa elinkeinopalveluja ja tarjoaa teollisuustoimitiloja yritysten käyttöön. Se osallistuu yhdessä yhteistyökumppaneiden ja alueen yritysten kanssa alueellisiin kehityshankkeisiin ja tukee yritysten kasvua ja kehitystä.

———————

Aiheeseen liittyviä projekteja

BR Pilot Plant

BR Pilot Plant on Pohjois-Pohjanmaan liiton rahoittama EAKR-hanke, jossa selvitetään mahdollisuuksia perustaa litium-ioni akkujen pilottikierrätyslaitos ja kehitys- ja testausympäristö (virtuaalinen koetehdas) Ylivieskaan osaksi akkupuistoa

Hankkeen avulla selvitetään uudenlaisen litium-ioni akkujen purkamiseen liittyvän kansainvälisen tason tuotannollisen toiminnan ja teknologiakehityksen toimintaedellytykset ja reunaehdot alueella. Lisäksi saadaan uuttaa tietoa akkujen purkamistoimintaan läheisesti liittyvien toimintojen kuten akkujen kuljetuksiin, varastointiin ja muihin logistiikkakysymyksiin, koulutustarpeisiin sekä sijoittumiseen ja erilaisiin ympäristömääräyksiin liittyen.

Hankkeen välittömät tulokset toimivat päätöksenteon tukena akkujen kierrätyslaitoksen perustamiselle Ylivieskaan. Hanke mahdollistaa uudentyyppisen teollisen toiminnan syntymiselle alueelle. Pilottilaitos ja siihen liittyvä kansainvälinen yhteistyö ja kiertotalouskokonaisuus mahdollistavat uusien ja muualta siirtyvien yritysten tuoman työpaikkojen lisäyksen.

Pitkällä aikavälillä hankkeen tulokset mahdollistavat laajemmat ja monipuolisemmat kasvu- ja vienti- sekä kansainvälistymisnäkymät alueen tuotannolliselle teollisuudelle sekä siihen liittyville palveluille sekä lisäävät alueen yleistä vetovoimaisuutta, dynaamisuutta ja kilpailukykyä. Lisäksi tulokset mahdollistavat uudentyyppisen roolin kansainvälisissä hankkeissa tukeutuen akkukierrätyksen pilottilaitokseen ja virtuaalitehtaan muodostamaan kokonaisuuteen ja sen tuomaan osaamiseen. Hankkeen tulokset vahvistavat Pohjois-Pohjanmaa alueen yritysten valmiutta siirtyä seuraavan teknologiavaiheeseen tuotannollisessa teollisuudessa ja hyödyntää mahdollisimman hyvin uusien prosessointimenetelmien ja Industry 4.0:n tarjoamat mahdollisuudet nopeasti kasvavalla akkuteollisuusalalla Euroopassa ja globaalisti.

SAAROB

Centria-ammattikorkeakoulu on vahva alueellinen hanketoimija, jolla on kokemusta teollisuuden ja oppilaitosten yhteishankkeista. Osaamisen osalta Centria-ammattikorkeakoulun vankka kokemus digitaalisen tehdasinfrastruktuurin, robotiikan, cobotiikan ja tekoälyn sovelluksissa sekä tuotantoteknologioiden sekä ympäristökemian alla tukee modernin akkujen käsittelylaitoksen osaamistarpeita tulevaisuudessa.

Centrian SAAROB-hankkeen tutkimuksellisena tavoitteena on etsiä ja hyödyntää uuden sukupolven robotiikan-, digitalisaation-, sekä älykkään automaation avulla turvallisia ja tuottavuutta edistäviä ratkaisuja, ideoita ja toimintamalleja tulevaisuuden akkukierrätyksen logistisiin haasteisiin. Hankkeessa luodaan ja testataan turvalliseen akkuteknologian jälleenhyödyntämiseen keskittyvä robotisoitu tutkimus-, kehitys-, ja innovaatioympäristö sekä luodaan tämän ympärille konsepti, jonka avulla tutkimustulokset välitetään yrityksille ja toimijoille sovellusdemonstraatioiden, prosessisimulointien ja tietopakettien muodossa.

Hankkeen tuloksena alueelliset yritykset, toimijat ja kuluttajat saavat konkreettista tutkimustietoa ja ratkaisumalleja sähköautojen akkuteknologian jälleenhyödyntämisprosessista osana tulevaisuuden vähähiilistä yhteiskuntaa. Tulokset palvelevat alueen teollisuusyrityksiä tuottamalla soveltuvaa tietoa akkujen kierrätykseen liittyvän teollisuuden toimintaedellytyksistä alueella, ja sitä voidaan hyödyntää alueen elinkeinojen kehittämisessä myös muilla aloilla. Tieto vahvistaa yritysten valmiutta siirtyä seuraavan teknologiavaiheeseen tuotannollisessa teollisuudessa ja hyödyntää mahdollisimman hyvin mm. uusien käsittelymenetelmien ja Industry 4.0:n tarjoamat mahdollisuudet akkujen kierrätysteollisuudessa. Hanketta rahoittaa Pohjois-Pohjanmaan liitto EAKR-rahoituksena.

Ylivieska on vakaasti kehittyvä alueellinen kasvukeskus, jonka väkiluvun on väkiluvun on ennakoitu kasvavan 18% vuoteen 2040 mennessä. Myös työpaikkojen kasvuennuste on hyvä: tavoitteena on, että kaupungissa on 1000 uutta työpaikkaa vuoteen 2030 mennessä. Ylivieska on ympäryskuntiensa keskuskaupunki ja tekee systemaattisesti töitä sen eteen, että sen noin 100 000 asukkaan markkina-alue jatkaa kasvamistaan. Vuonna 2019 Ylivieskan alue nousi merkittävien kaupunkiseutujen joukkoon (MDI 2019: Kaupunkiverkkotutkimus).

Ylivieska tarjoaa loistavat mahdollisuudet teollisen sektorin yrityksille ja hyvän ympäristön liiketoiminnalle. Ylivieskassa on vahvaa teollisuutta, jonka erityisosaamista käyttävät monet alueen yritykset. Muiden alueen yritysten kanssa verkostoituminen vähentää suhdannevaihteluiden vaikutusta ja investointiriskiä, mikä mahdollistaa yrityksesi kasvun. Useat oppilaitokset tarjoavat pätevää työvoimaa. Rakennus- ja rakennustarviketeollisuus sekä metalliteollisuus ovat erityisen vahvoja aloja alueella.

Hyvä sijainti on yksi Ylivieskan kasvun salaisuuksista. Ylivieskan sijainti kantateiden risteyksessä ja Pohjanmaan radan varrella on edullinen: voit matkustaa Ylivieskaan tai Ylivieskasta junalla ja työskennellä matkustaessasi. Lue lisää VR:n Yrityspalveluista. Myös tavarakuljetusten osalta siajinti on erinomainen, suorien rautatieyhteyksien lisäksi lähin satama on vain 50 kilometrin päässä ja lähimmälle lentokentälle on matkaa noin 70 km.

Tilat ja laitteet

Älykäs testaus, simulaatiot ja robotiikkaympäristö

Battery Park -laboratorioihin kuuluu useita laboratorioita sekä testaus ja demonstraatiotiloja, joissa yritykset ja T&K-toimijat voivat tutkia, testata ja demonstroida uusia ratkaisuja ja teknologioita.

Tuotantoteknologian kehittämislaboratorio

Centrian tuotantoteknologian tutkimusryhmällä on käytössään kehittyneet ja nykyaikaiset robotiikan tutkimus ja kehittämisympäristöt, joissa toteutetaan robotiikan ja tuotantoautomaatioteknologian soveltavaa tutkimusta ja kehitystä. Laboratoriot on varusteltu uusimmilla tutkimusalueeseen liittyvillä laitteistoilla ja varusteilla, joita ovat mm. yhteistyörobotit, mobiilirobotit, teollisuusrobotit, dronet, konenäkö- ja sensoriteknologiat, simulointi- VR ja AR-laitteistot jne. Tutkimuksen ja kehityksen painopistealueita ovat yhteistyörobotiikka, konenäkö, tekoäly, robotiikan turvallisuus, sekä ketterät ja älykkäät tuotantoympäristöt. Siirrettävien laitteistojen avulla robotiikan demonstraatioita on mahdollista toteuttaa myös yritysten omissa tuotantotiloissa.

Akkulaboratorio

Laboratorion tärkein osa on li-ion akkujen tuotantolinja ja akkujen testausjärjestelmä, jossa jopa 48 akkua voidaan testata samanaikaisesti. Laboratorion erikoisuus on kuivahuone, joka on olennainen li-ion akkujen tuotannossa ja testauksessa. Laboratorion erikoislaitteita voidaan käyttää osana täydellistä laboratoriomittakaavassa rakennettavaa litiumioniakkujen valmistuslinjaa, missä akkuja voidaan valmistaa tutkimustarkoituksiin. Muut laitteet mahdollistavat akkukennojen monipuolisen tutkimuksen ja testaamisen. Laboratorio tarjoaa erinomaiset mahdollisuudet uusien akkukemikaalien ja li-ion akkuteknologioiden tutkimukselle ja kehitykselle.

Tuotantoteknologian laboratoriotilat ja laitteet

- Robotit

- Cobotit

- 3D-tulostimet

- 3D-skannerit

- Laserskannaus

- CNC koneistuskeskus Deckel Maho 80T

- VR-laitteet ja sovellukset

Robotit ja cobotit

- ABB IRB 140/IRC5

- ABB IRB 4400

- ABB IRB 6700

- Fanuc LR Mate 200iD

- KUKA KR6 R900 sixx/K C4

- Motoman MH6D/DX100

- Omron LD250 mobiilirobotti

- Omron TM12

- Universal Robot UR3 cobotti

Turvalaitteet

- SICK M4000 turvavaloverho

- SICK S300 turvalaserskanneri

- Safety Eye turvakamera

- Kameralaitteisto

- Konenäkökamerat

Virtuaalinen tehdas on digitaalista ja todellista ympäristöä yhdistävä simulaatioympäristö, joka mahdollistaa akkujen valmistus- ja kierrätysteknologioihin liittyvän kehittämisen, tutkimuksen, testauksen ja koulutuksen.

Virtuaalitehtaassa tehdasprosessien mittakaava voidaan kutistaa ja prosessiaikoja kiihdyttää. Tällä tavoin monimutkaiset ilmiöt tulevat näkyviksi, konkreettisimmiksi ja niiden suhteen voidaan toimia tehokkaammin.

Edut:

- Teollisuusvalmistajat ja muut toimijat voivat testata erilaisia teknisiä ratkaisuja ennen kuin tekevät raskaita investointeja tuotantolinjoihin, laitteisiin ja teknologioihin

- Mahdollistaa nopeamman ja tehokkaamman tuotantoprosessien suunnittelun

- Tukee korkeampia tuotantotavoitteita ja prosessien laatutavoitteita

- Tarjoaa uusia mahdollisuuksia akkuteknologian kehitykseen, suunnitteluun ja tutkimukseen

- Tehokas tapa perehdyttää uusi ja nykyinen henkilöstö laitteiden käyttöön ja akkulaitoksen prosesseihin.

Virtuaalinen Battery Information R&D Centre tarjoaa runsaasti palveluita ja tietoa akkujen kierrätykseen ja akkuteollisuuteen liittyvistä aiheista.

Julkaisut

- Tutkimusjulkaisut ja -raportit

- Artikkelit

- Mielipidekirjoitukset

Koulutus

- Lyhyet lisä- ja täydennyskoulutukset

- Pitkät käytännön koulutukset ja teoreettiset kurssit

- Akkuakatemia (paikallinen ja virtuaalinen)

- Kurssikomponentit kumppaniyrityksille

Konsultointi

- Testaus- ja tutkimustulosten tietokanta

- Tietoa markkina- ja teknologiatrendeistä

- Tietoa alan parhaista käytänteistä

R-Yrityspuisto

Tuleva uusi teollisuuskeskittymä, R-Yrityspuisto Ylivieskassa, tarjoaa yrityksille täysin uusia menestymisen mahdollisuuksia. Rakentuvan alueen veturiyrityksenä toimii Recion Oy:n pitkät perinteet omaava putkistotehdas, joka osaamiseen kuuluvat myös erilaisten komponenttien ja erikoistuotteiden valmistus ja pintakäsittely. Recionin Ylivieskan tehtaasta tulee nykyaikainen yrityskeskus, joka kokoaa uudella tavalla yhteen yrityksiä, tieto- ja taitopääomaa ja palvelee tulevaisuuden liike-elämän ja teollisuuden tarpeita. Recion seurakseen alan uusia toimijoita, jotka hyötyvät sijainnista, Recionin tuotantolaitteista ja tiloista, materiaalihankinnoista ja eri toimijoiden välisistä synergioista.

Teollisuusalueelle tulee olemaan ominaista mm. teknologiateollisuus, teollisuus 4.0 (i4.0) eli seuraavan sukupolven tuotantoteknologiat, kiertotalous ja akkujen kierrätysteknologiat. Centria ammattikorkeakoulun rooli tulee korostumaan etenkin i4.0:n omaksumisessa. Ylivieskan kaupungin elinkeinopalvelut ja YTEK Ylivieskan Teknologiakylä Oy ovat myös tiiviisti mukana hankkeessa ja tarjoavat yrityksille palveluita, kehittävät yritysten toimintaedellytyksiä ja tukevat kannattavien yritysten ja uusien työpaikkojen syntyä Ylivieskaan.

Testaus- ja demotiloja sekä toimistoiloja on tarjolla Centria ammattikorkeakoulun Vierimaantien kampuksella Ylivieskassa. Teollista tuotantotilaa on vuokrattavissa Recion Oy:n R-Yrityspuistossa.

Battery Recycling Innovation Park -hankkeen tavoitteena on synnyttää Ylivieskaan uutta akkuteollisuuteen ja akkujen kierrätykseen liittyvää yritystoimintaa perinteisen teollisuuden rinnalle. Akkupuisto tarjoaa alueelle sijoittuville yrityksille toimisto- ja tuotantotiloja, kattavan kumppaniverkoston ja matalan kynnyksen T&K-palvelut. Ota yhteyttä, niin kerromme lisää!

Hyödyt Akkupuiston yrityksille

- Markkinanäkyvyyttä ja laajan verkoston tuomat kontaktit

- Innovatiivinen liike- ja yrittäjäyhteisö

- Centria ammattikorkeakoulun vahva osaaminen digitaalisen tehdasinfrastruktuurin, robotiikan, cobotiikan ja tekoälyn sovelluksissa sekä tuotantoteknologioiden ja ympäristökemian alalla

- Mahdollisuus hyötyä Akkupuiston kansainvälistä yritysverkostosta, T&K-organisaatioista, rahoittajista ja niiden välisestä synergiasta

- Toimisto- ja tuotantotiloja sekä mahdollisuus käyttää edistyksellistä ja hyvin varusteltua laboratoriota testaukseen ja pilotointiin

- Erinomaiset logistiset yhteydet pääjunaradan varressa, josta on lyhyet yhteydet mm. alueen satamiin Kokkolassa, Oulussa ja Kalajoella. Myös lentokentät sijaitsevat suhteellisen lähellä ja alueelta on hyvät maantiekuljetusyhteydet eri ilmansuuntiin

- Sijaintia tukevat myös läheisen Kokkolan vahvat kemianteollisuuden ja metalliteollisuuden klusterit

- Mahdollisuus osallistua Akkupuiston tulevaan suunnitteluprosessiin

Akkupuiston palvelut

- Elinkeinopalvelut start-up yrityksille ja yrityksille elinkaarensa eri vaiheissa (esim. verkostoituminen, B2B kumppanipalvelu, kansainvälistyminen)

- Tukea avainhenkilöiden palkkaamiseen ja byrokratiasta huolehtimiseen

- Tietopaketit yrityksille

- Kumppaneiden ja verkostojen etsintä

- Toimisto- ja tuotantotiloja

- T&K-palvelut, tilat ja laitteet

- Aktiivinen kumppaniyhteistyö tutkimus- ja kehityshankkeissa, mukaan lukien T&K -rahoituspalvelut ja -tuki

- Koulutuspalvelut

Liity verkostoon

- Mahdollisuus osallistua uusien akku- ja kierrätysteknologioiden ja uuden liiketoiminnan kehittämiseen

- Keliberin litiumkaivos lähiseudulla Kaustisella, on Euroopan suurin litiumkaivos

- Vaasan sijoittuvat Johnson Mattheyn ja Freyrin akkuprekursoritehtaat

- Terrafame monimetalli-kaivosyhtiön 240 miljoonan investointi akkukemikaalitehtaaseen

- Suomessa on toimivia kobolttikaivoksia sekä suunnittelu- ja etsintähankkeita

- Boliden Kokkolassa on Euroopan toiseksi suurin sinkin tuottaja

- Freeport Cobaltilla on kattava valikoima kobolttipohjaisia kemiallisia ja katalyyttisia sovelluksia sekä tuotteita jauhemetallurgian ja akkuteollisuuden tarpeisiin

- Umicore Finlandin kobolttijalostamo

- Useiden satojen miljoonien alustavat investoinnit katodiaktiivisten materiaalien tuotantolaitoksiin lähialueella ja muualla Suomessa

- Akkukierrätysteknologiayritykset Akkuser ja Tracegrow

- Alueella on laaja verkosto eri teollisuuden alojen alihankinta- ja muita yrityksiä

- Centria ammattikorkeakoulun Digital Factory Infrastructure -projekti tulossa

- Muita tukevia projekteja menossa tai suunnitteilla

Yritys- ja kumppaniverkostoomme kuuluu jo yli 50 koti- ja ulkomaista yritystä ja T&K-toimijaa. Verkostomme mahdollistaa uusien liiketoimintamallien kehittämisen, yritysten ja T&K-toimijoiden yhteiset tutkimus- ja tuotekehityshankkeet sekä kansainväliset kontaktit ja yhteistyön.

Miksi sijoittaa akkupuistoon?

- Akkumarkkinoiden arvoksi Euroopassa vuoteen 2025 mennessä on ennustettu 250 miljardia euroa

- Ilmastonmuutos ja hiilijalanjäljen pienentäminen ovat luoneet valtavan kysynnän kestävän kehityksen mukaisille akkujen kierrätysteknologioille

- EU on asettanut strategiset tavoitteet innovatiivisen, kestävän ja kilpailukykyisen akkuekosysteemin luomiseksi Eurooppaan

- Suomessa on laajaa akkuarvoketjuun liittyvää osaamista: vahvaa kaivosteollisuutta ja raaka-aineiden prosessiteollisuutta sekä akkujen valmistamiseen, käyttöön ja kierrätykseen liittyvä teknologiaosaamista

- Suomen tavoitteena on päästä johtavaksi teknologia- ja palveluasiantuntijaksi globaaleilla markkinoilla ja tavoitella kärkipaikkaa akkujen kierrätyksen osaajana

- Ylivieskan akkupuistossa tulee toimimaan useita uusia korkean teknologian startup ja PK-sektorin yrityksiä. Se tarjoaa erinomaiset tilat, laitteet ja tuotekehitysympäristön sekä vahvan kansainvälisen verkoston luomat mahdollisuudet uusien läpimurtojen kehittämiseen akkuteollisuudessa

- Ylivieskalla on hyvät mahdollisuudet toimia esimerkiksi litium-ioni akkujen kierrätyslaitoksen sijoituspaikkana

- Erinomaiset logistiset yhteydet valtakunnan pääjunaradan varressa, josta on lyhyet yhteydet mm. alueen satamiin Kokkolassa ja Oulussa sekä Kalajoella. Myös lentokentät sijaitsevat suhteellisen lähellä ja alueelta on hyvät maantiekuljetusyhteydet eri ilmansuuntiin

- Sijaintia tukevat myös läheisen Kokkolan vahvat kemianteollisuuden ja metalliteollisuuden klusterit

- Lähialueelle Vaasaan on sijoittumassa Johson Mattheyn sekä Freyrin akkuteollisuuden komponentteja tuottavat prekursoritehtaat. Akkupuiston partneriverkostossa on yli 50 yritystä ja tutkimuslaitosta eri puolilta Eurooppaa

- Alueen vahva kaivosteollisuus ja niihin liittyvät kehityshankkeet tukevat akkuekosysteemin syntyä alueelle

New developments in battery technology are changing the way we transport and power the world and battery technology has become a highly important investment theme both globally and nationally. Ylivieska region has excellent prerequisites for becoming an important link in the Finnish battery value chain. Contact us and find out more about opportunities in the Battery Park.